Machine Model : CPU30J-5C

Excellent Features

Sanitary waste facilities create harsh

environments but urethanes outperform other

elastomers in these guide wheels.

Mining separator screens are another example

in which superior abrasion, impact and cut

resistance combine with resilience to provide

long service life.

INTRODUCTION

The CASTECH machines DB9 3000 series have been purposely studied to accurately meter and mix hot cast elastomeric systems. The structure of the CASTECH machines is designed to

transform either polyurethane systems composed by prepolymer, polyol and chain extenders (like

the majority MDI based systems) or polyurethane systems composed by two prepolymers and a chain extender (like the majority of TDI based systems). The machine can work practically all the polyurethane systems, including microcellular elastomer foams.

Microphase-separated Morphology in Polyurethane Elastomers

Wide Range of Processing Techniques

Liquid injection moulding (low pressure)

Transfer moulding (multiple precision parts)

Rotational moulding (for hollow castings)

Dipping (long pot-life and heat activated)

Multi and single component

Technical parameters:

1. Output : 3~10Kg/min

2. Three-phase AC 400V + zero line + (ground) frequency: 50HZ total power 35KW wire 10 square line

3. Air source: The outer diameter of the inlet pipe is 8mm and the pressure is 0.6~0.8MPa.

4. Three components mixing ratio: A: B= 100: 5 ~ 20

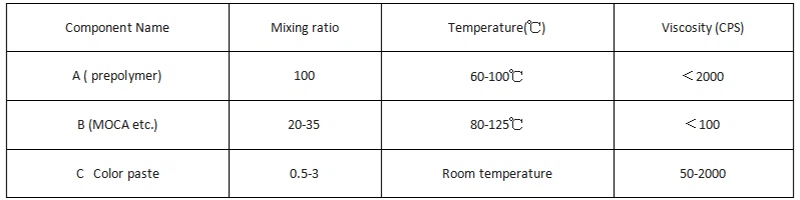

Raw Chemical Components

Hot Tags: resin elastomer casting equipment, China, suppliers, manufacturers, factory, wholesale, buy, cheap, bulk, customized, low price, in stock, free sample, made in China, PU Injection Machine, Polyurethane Elastomer Testing Machine, PU Elastomer Middle Temperature Casting Machine, PU dispensing Machine