Tanks equipment: All tanks are equipped with a stirrer, its shape has been purposely designed in order to avoid a prolonged contact between materials and tank surface. The

absence of thermal inertia from hot air heating, avoids harmful thermal stress

to the material.

The bottom of the vessel has a cylindroconical shape in order to allow to work

also with a very low amount of material and is equipped with a special valve

with integral holding fluorinated seal, which prevents deposits of material. This

arrangement avoids undesirable blockage. The valve also has a special seal on the drive shaft of the ball, which prevents the entry of undesirable air from

the bottom of the tank during degassing operation.

Tanks are equipped with electronic level sensors.

Stirrer speed range: Stirrers are powered by brushless motors and can work in range between 0 and 50 Rpm.

Visual levels: The tanks can be inspected trough an illuminated specula equipped with a borosilicate glass, resistant to heat and vacuum.

Electronic levels:

Tanks are equipped with a minimum level sensor and an alarm.

Technical parameters:

1. Output : 3~10Kg/min

2. Three-phase AC 400V + zero line + (ground) frequency: 50HZ total power 35KW wire 10 square line

3. Air source: The outer diameter of the inlet pipe is 8mm and the pressure is 0.6~0.8MPa.

4. Three components mixing ratio: A: B= 100: 5 ~ 20

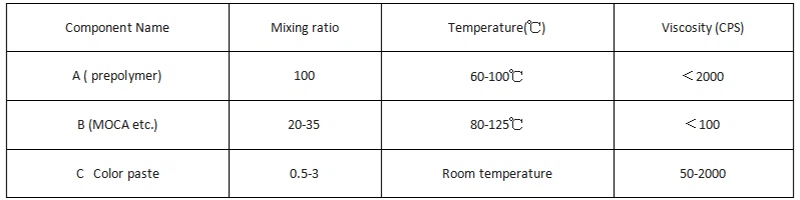

Raw Chemical Components

Hot Tags: heavy duty urethane wheel coating machine, China, suppliers, manufacturers, factory, wholesale, buy, cheap, bulk, customized, low price, in stock, free sample, made in China, PU Elastomer Middle Temperature Casting Machine, Polyurethane Elastomer Testing Machine, PU dispensing Machine, PU Injection Machine